Textile printing and dyeing wastewater case

Textile printing and dyeing wastewater treatment

It is one of the major pollutants in the process of adding acid and alkali to the surface of cotton fabric and textile fiber, as well as in the process of textile processing.

According to the action principle and removal object of technical measures, textile wastewater treatment process can be divided into physical treatment method, chemical treatment method and biological treatment method. The main purpose of textile wastewater treatment by physical action is to separate and remove insoluble suspended particles in the wastewater. The main textile wastewater treatment processes include:

1. The grid is a frame with a certain interval made of a group of parallel metal grid bars. It is placed vertically or obliquely on the wastewater channel to remove the coarse suspended solids and floating objects in the textile wastewater, so as to avoid the blockage of the rear device. Screen is a filtering device made of perforated filter plate or metal mesh to remove finer suspended solids.

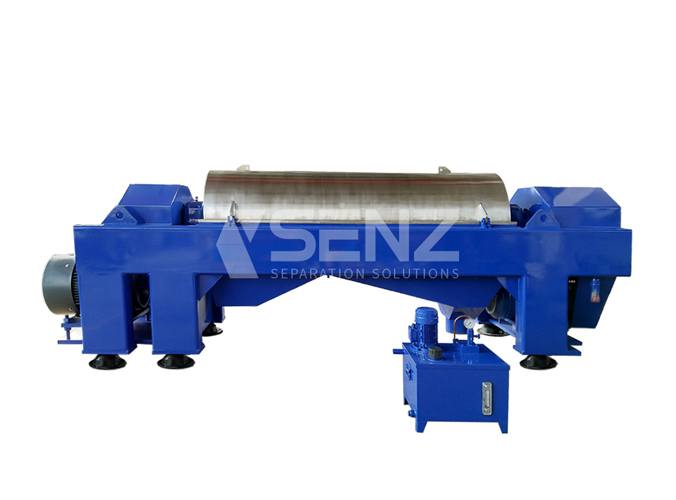

2. Centrifugal separation uses centrifugal action to separate suspended solids with different quality from water body. The separation equipment includes flow separator and horizontal screw centrifuge.

3. In the air flotation method, air is introduced into the wastewater to produce fine bubbles, which are attached to the fine particle pollutants to form a floating body with a density less than that of water and float up to the water surface. It is mainly used to separate fine particulate pollutants whose density is close to or smaller than water and cannot be precipitated by gravity.

4. The sedimentation method uses gravity to sink the solid matter heavier than water in the wastewater and separate it from textile wastewater. It is mainly used to remove inorganic sand particles in the dust and sand tank, remove suspended organic matter heavier than water in the initial sedimentation, remove biological sludge in the biological treatment effluent in the secondary sedimentation, remove flocs formed by coagulation after the coagulation process, separate water in sludge in the sludge concentration tank and concentrate sludge. This method is simple and effective.

In the textile wastewater treatment process, the precipitation method combined with centrifugal separation is used for treatment, and the effect is particularly good. It can effectively remove more than 99.5% of the suspended solids in the wastewater. After dehydration, the sludge can be accumulated without dripping during transportation. The textile printing and dyeing industry is a major producer of industrial sewage. The sewage mainly contains the dirt, grease and salts on the textile fiber, as well as various additional sizes, dyes, surfactants, additives, acids and bases in the processing process. Wastewater is characterized by high concentration of organic matter, complex composition, deep and changeable color, large change in pH, large change in water quantity and quality. It is difficult to treat industrial wastewater. Shenzhou centrifuge equipment adopts the principle of centrifugal force, with large processing capacity, good effect and high efficiency. This kind of wastewater must be pretreated with chemicals and then treated in series in order to discharge stably up to the standard.

Printing and dyeing wastewater refers to the wastewater discharged from the pretreatment, dyeing, printing and finishing of cotton, wool, hemp, silk, chemical fiber or blended products. Printing and dyeing wastewater has the characteristics of large amount of water, high content of organic pollutants, deep color, large alkalinity and large change of water quality. It is a kind of industrial wastewater that is difficult to treat. There are four main treatment methods for printing and dyeing wastewater, including physical treatment, chemical treatment, biological treatment and alkali reduction treatment. The water quality of printing and dyeing wastewater varies with the type of fiber and processing technology, and the pollutant components vary greatly. Printing and dyeing wastewater generally has the characteristics of high concentration of pollutants, many kinds, toxic and harmful components and high chromaticity. Generally, the pH value of printing and dyeing wastewater is 6 ~ 10, CODcr is 400 ~ 1000mg / L, BOD5 is 100 ~ 400mg / L, SS is 100 ~ 200mg / L, and the chromaticity is 100 ~ 400 times.

Horizontal screw centrifuges are generally used in the dewatering process of printing and dyeing sludge, which can greatly reduce the moisture content of printing and dyeing sludge after biochemical or physicochemical treatment, minimize the amount of sludge, and facilitate subsequent treatment. The equipment covers a small area, the process is simple, and the treatment effect of printing and dyeing wastewater is stable.

Machine installation, commissioning on the customer's site