Product description

Mobile sludge dewatering treatment equipment is an efficient environmental protection system. The volume reduction of sludge after treatment is up to 90%, and the solid content of cement cake is usually 20% ± 5%. The mobile sludge dewatering system developed by Shenzhou is mainly used in septic tanks, garbage service stations, oily sewage, car washing water, sewage treatment plants, ditches, ponds and other occasions requiring solid-liquid separation.

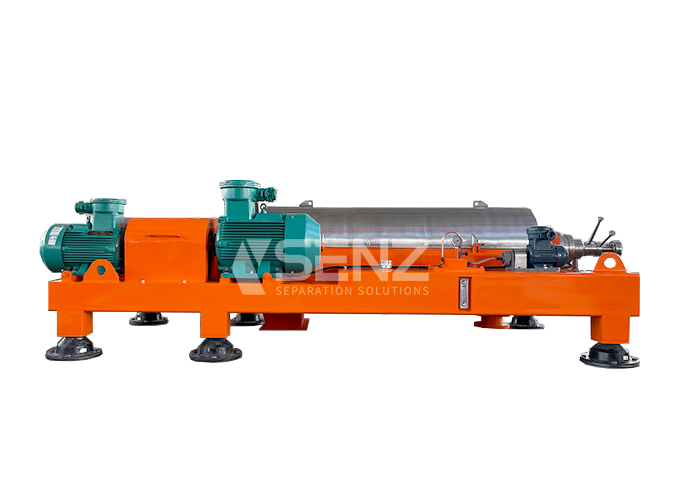

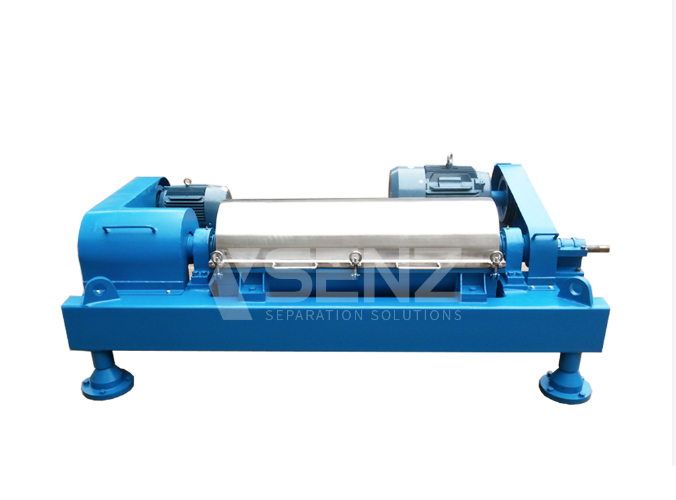

Mobile sludge dewatering and treatment equipment, including truck (carriage needs to be reconstructed), sludge centrifugal dehydrator, sludge pipe, dosing system, dosing pipe, sludge suction pump, generator set and on-site control box. The truck pulls the whole set of equipment to the destination and stops near the sludge thickener of the sewage station. The sludge pipe is connected with the sludge suction pump and sludge centrifugal dehydrator. The sludge pipe adopts high-pressure water belt pipe, and the movable joint is easy to disassemble, It is easy to carry and the length can be selected. Put the sludge suction pump into the bottom of the sludge tank, start the generator set, add the sludge flocculant into the dosing system, start the sludge centrifugal dehydrator and sludge suction pump, and then the sludge flocculant evenly stirred by the drug dissolving mixer is transported to the sludge centrifugal dehydrator by the dosing metering pump. The invention can flexibly and conveniently go to various small sewage treatment stations to treat all kinds of sludge, It realizes the difficult problem of sludge disposal in small sewage treatment stations and reduces the possibility of secondary pollution during sludge outward transportation and treatment.

The equipment can also be an integrated screw stacker system and equipped with trucks to realize sludge dewatering at any place and at any time. The equipment is new and practical, and can be moved to work. The electric control box can be used to control the whole work flow, making various operations more convenient; At the same time, sustainable electric work, high work efficiency, safety and environmental protection, effectively reducing the labor intensity of staff. It is also equipped with a generator set, which can continue to work without three-phase electricity.

Equipment characteristics

The design is compact, and all equipment is concentrated in one compartment.

The mobile system can quickly respond to emergencies and provide * type operation and maintenance services

The treatment effect is good, and the volume reduction of sludge reaches 60% - 90%

The on-site civil engineering area is small and movable, which greatly reduces the transportation time, operation cost and labor cost

Simple operation and low maintenance cost

Material selection

According to the user's requirements, the product contact can be made of austenitic stainless steel (321, 316L...), Haines alloy, titanium alloy or other anti-corrosion materials.

Technical parameter

Users can reasonably select the working parameters of the centrifuge according to the physical properties of the separated material (suspension), separation requirements, treatment capacity, process requirements and other factors, so as to obtain satisfactory separation effect and economic benefits. Colors and materials can be customized.