Background technology

The method and device for treating heparin sodium casing production wastewater are hydrolysated and extracted from the production of heparin sodium by centrifugal separation, primary filtration, two filtration, concentration, spray drying, drying and reverse osmosis treatment to achieve high concentration protein recovery and extraction. The purified wastewater can be recycled and the outlet of the centrifuge clear liquid is connected with the liquid inlet of the liquid collection tank. The outlet of the liquid collecting tank is communicated with the fine filter device through the conveying pump A, and the fine filtration device is communicated with the inlet of the nanofiltration membrane filter through the conveying pump B, and the outlet of the nanofiltration membrane filter device is communicated with the reverse osmosis membrane device, and the outlet of the turbid liquid of the nanofiltration membrane filter device is connected with the feed inlet of the falling film evaporator A, and the A discharge port of the falling film evaporator is connected with a spray dryer. The beneficial effect of the invention is to realize the recovery and extraction of high concentration protein, recycle and reuse the purified wastewater, reduce environmental pollution and improve economic benefits.

Heparin sodium is a biomedical intermediate, which has the effects of anticoagulant and preventing thrombosis. It has high clinical value in bleeding of patients with nephropathy and acute myocardial infarction. It is abundant in animal small intestine, especially in pig small intestine mucosa. At present, in the production process of enzymatic hydrolysis and extraction of heparin sodium, the discharged enzymatic hydrolysis wastewater not only contains a large amount of solid suspended solids, but also contains high concentrations of organic pollutants such as protein. If the wastewater is directly discharged into rivers and lakes without treatment, it will consume a large amount of dissolved oxygen in the water body, corrupt the water body, deteriorate the water quality and cause serious pollution to the environment.

The method and device for treating wastewater from heparin sodium casing production can realize the recovery and extraction of high concentration protein, recycle and reuse the purified wastewater, reduce environmental pollution and improve economic benefits.

Technical scheme

Treatment of heparin sodium casing production wastewater, including the following process steps: centrifugal separation, primary filtration, two filtration, concentration, spray drying, drying, reverse osmosis treatment.

Process steps

<1> Centrifugation: the wastewater produced in the production of heparin sodium is extracted by enzymatic hydrolysis as raw water, the raw water and flocculant solution are mixed and injected into centrifuge 1, and the protein suspension in the raw water is removed by the centrifugal force generated by the high-speed rotation of centrifuge 1 to obtain protein clarification solution I;

<2> Primary filtration: filter the protein clarification solution I obtained in step 1 with fine filtration device 3 to remove the remaining solid impurities and obtain liquid II;

<3> Secondary filtration: the liquid II obtained in step 2 is further filtered through the nanofiltration membrane filtration device 4 to obtain protein concentrate III and nanofiltration produced water;

<4> . concentration: pump the protein concentrate III obtained in step 3 into the falling film evaporator A6 for circulating treatment, heat, evaporate and concentrate to obtain solution V;

<5> and spray drying: the solution V of step 4 is dried by spray dryer 7, and the finished product I is obtained.

<6> Drying: drying the protein suspension obtained in step 1 to obtain protein II;

<7> Reverse osmosis treatment: the nanofiltration produced water obtained in step 3 is treated by reverse osmosis membrane device 5 to obtain reverse osmosis treated concentrated water and reverse osmosis treated produced water. The reverse osmosis treated produced water is reused in the production of heparin sodium.

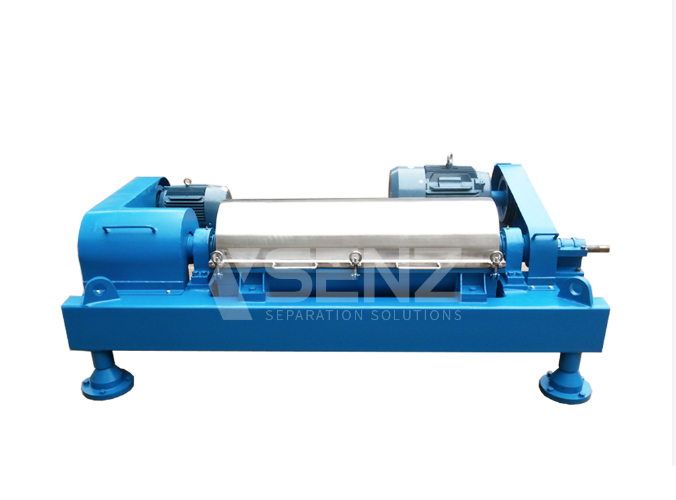

The centrifuge 1 described in step 1 is a horizontal spiral sedimentation centrifuge.

The flocculant described in step 1 is polyacrylamide flocculant.

The fine filtration device 3 described in step 2 is a bag filter.

The recovery rate of soluble protein of the nanofiltration membrane filtration device 4 described in step 3 is more than 90%.

The protein concentrate III described in step 4 is evaporated and concentrated 10 times to obtain solution v.

The falling film evaporator A6 described in step 4 is a three effect falling film evaporator a.

The concentration and evaporation time of the falling film evaporator A6 described in step 4 is 2-5h, the pressure is 0.18-0.22mpa, and the temperature is controlled at 115-125 degrees.

The inlet temperature of the spray dryer 7 described in step 5 is 155-180 degrees.

<8> Evaporative crystallization: evaporate and crystallize the concentrated water from reverse osmosis treatment in step 7 to obtain anhydrous sodium chloride and recycle it into production.

A device for treating wastewater from heparin sodium casing production wastewater comprises a centrifuge 1, a liquid collecting tank 2, a fine filter device 3, a nanofiltration membrane filter 4, a reverse osmosis membrane device 5, a falling film evaporator A6, a spray dryer 7, a conveying pump A8 and a conveying pump B9, and a clear liquid outlet of centrifuge 1 is connected with the 2 liquid inlet of the liquid collecting tank, and the 2 liquid outlet of the liquid collection pool is communicated with the 3 filter of the fine filter device through the conveying pump A8. The fine filtration device 3 is communicated with the inlet 12 of the nanofiltration membrane filter 4 through the conveying pump B9, and the outlet port of the nanofiltration membrane filter 4 is connected with the inlet 15 of the reverse osmosis membrane device 5, and the 14 outlet of the filtration membrane 4 of the nanofiltration membrane is connected with the A6 inlet of the falling film evaporator, and the discharge port of the falling film evaporator A6 is connected with the spray dryer 7.

The nanofiltration membrane filtration device 4 comprises a tank body 10, a nano separation membrane 11 is arranged in the tank body 10, and the fine filtration device 3 is a bag filter.

One end of the nanofiltration membrane filtration device 4 is provided with a water inlet 12, the other end of the nanofiltration membrane filtration device 4 is provided with a water outlet 13, and the middle of the nanofiltration membrane filtration device 4 is provided with a turbid liquid outlet 14.

One end of the reverse osmosis membrane device 5 is provided with a water inlet 15, the other end of the reverse osmosis membrane device 5 is provided with a treated water outlet 16, and the middle of the reverse osmosis membrane device 5 is provided with a concentrated water outlet 17.

The device for treating wastewater from heparin sodium casing production also includes falling film evaporator B18. The concentrated water outlet 17 of reverse osmosis membrane device 5 is connected with the feed inlet of falling film evaporator B18, evaporated and crystallized to obtain sodium chloride, which is put into production for utilization.

One end of the feed pipe 19 of the flocculant 1 is inserted into the feed pipe 20 of the flocculant production device, and the other end of the feed pipe 19 of the flocculant 1 is also inserted into the feed pipe 20 of the flocculant production device.

The centrifuge 1 is a horizontal spiral sedimentation centrifuge.

Working principle

The wastewater produced in the production of enzymatic hydrolysis and extraction of heparin sodium is injected into the centrifuge, and the protein suspension in the wastewater is removed through the centrifugal force generated by the high-speed rotation of the centrifuge to obtain the protein clarification solution I, which is stored in the liquid collecting tank. The protein clarification solution I at the upper part of the liquid collecting tank flows into the fine filtration device through the transfer pump a, and is pumped into the nanofiltration membrane filtration device through the transfer pump B after being filtered once by the fine filtration device, Protein concentrate III and nanofiltration produced water are obtained under the action of nano separation membrane. The nanofiltration produced water finally flows out through reverse osmosis membrane device to purify wastewater. The purified wastewater can be introduced into industrial water circulation system through water pump for recycling; The protein concentrate III pump is pumped into the falling film evaporator A for recycling. After heating evaporation and concentration, the solution V is obtained. After the V is dried by spray dryer, the finished protein I is obtained, and the recovery and extraction of high concentration protein is realized.

Effect

1. Realize the recovery and extraction of high concentration protein, recycle and reuse the purified wastewater, reduce environmental pollution and improve economic benefits at the same time.

2. After further filtration by nanofiltration membrane filtration device, the COD in nanofiltration produced water decreased from 50000mg / L to 100000mg / L to 1000mg / L to 2000mg / L, effectively reducing the COD in nanofiltration produced water.

3. The water produced by nanofiltration is high salinity wastewater, which can be discharged up to standard after reverse osmosis treatment by reverse osmosis membrane device, or used in the production of heparin sodium.

Material selection

According to the user's requirements, the product contact can be made of austenitic stainless steel (321, 316L...), Haines alloy, titanium alloy or other anti-corrosion materials.