Product description

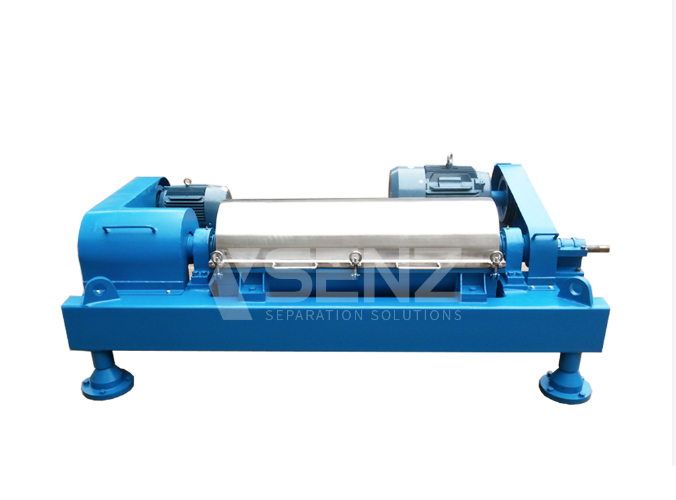

3-phase separator for food waste, 3-phase separator for oil residue and water of food waste, three-phase horizontal screw centrifuge.

The equipment is a three-phase separation centrifuge developed by our company on the basis of many years of application and combined with the current international advanced technology. It is suitable for the separation of liquid-liquid-solid materials. It has the advantages of simple structure and convenient operation. It can easily complete the three-phase separation. It has a wide range of application and strong adaptability.

The design of oil-water residue separator and kitchen waste oil residue water three-phase separation is mainly used for Solid-liquid-liquid three-phase separation of materials. It is a model developed in combination with more than 20 years of practical experience in the field of separation, and operates continuously and stably all day. It is mainly composed of driving device, differential, screw, drum, hood, base and control system.

It is required to meet the requirements that solid and liquid are insoluble, the specific gravity of the two liquids is different, and the specific gravity of solid is greater than that of liquid. Compared with two-phase horizontal screw centrifuge, the difference is that it can separate two-phase liquid.

Working principle

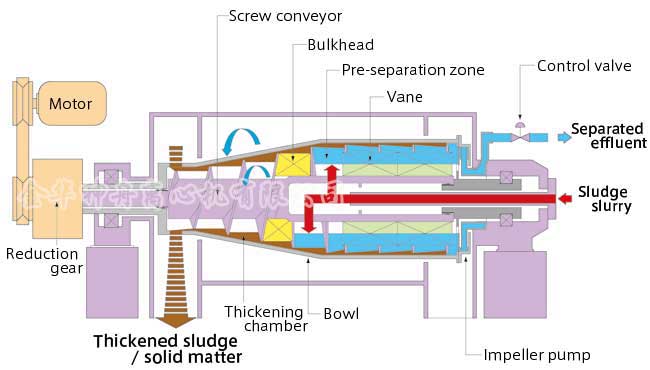

The structure of the special three-phase separator for kitchen waste is mainly composed of differential, screw, drum, cover, base, lubrication system, motor and other parts. Its working principle is: the suspension enters the drum through the feed pipe and spiral discharge port. Under the centrifugal force generated by high-speed rotation, the solid particles with large specific gravity are deposited on the inner wall of the drum. The spiral blade moving relative to the drum constantly scrapes the solid particles deposited on the inner wall of the drum and pushes them out of the slag discharge port. The liquid phase with different specific gravity will form two liquid rings in the drum and flow out through two different outlets of the big end cover.

The relative movement between the screw and the drum is completed by the differential. The shell of the differential is connected with the drum, and the output shaft is connected with the screw. While the main motor drives the drum to rotate, the auxiliary motor drives the rotation of the differential input shaft, and its output shaft transmits the torque to the screw according to a certain speed ratio, which completes the continuous separation process of materials by the centrifuge.

Performance characteristics

1. Wide application: it is suitable for Solid-liquid-liquid three-phase separation in chemical industry, light industry, food, kitchen waste, oil sludge, environmental protection and other occupations. Such as: oil-water residue separation in vegetable oil, oil in fish meal, hydrolyzed protein, residue separation, oil-water residue separation in oil field, etc.

2. High degree of automation.

3. The differential speed is adjustable.

4. Clean and pollution-free.

5. Good operation stability.

6. Strong corrosion resistance.

7. Simple operation and accurate conditioning.

Structural features

2205 duplex stainless steel is used for the straight section and cone section of the drum, and the centrifugal casting process is adopted.

Other parts of the conversion assembly are made of SS316L stainless steel.

The screw pusher is protected by YG6 wear-resistant alloy sheet, with long service life and easy maintenance and replacement.

The shunt port of the screw pusher and the slag discharge port of the drum are protected by wear-resistant alloy sleeve which is easy to replace, so as to delay the service life and maintenance cycle.

The bearing assembly can be removed during transportation to prevent damage to the support drum.

SKF bearings and NSK Bearings imported with original packaging are selected to improve the stability of the equipment and the service life of the bearings.

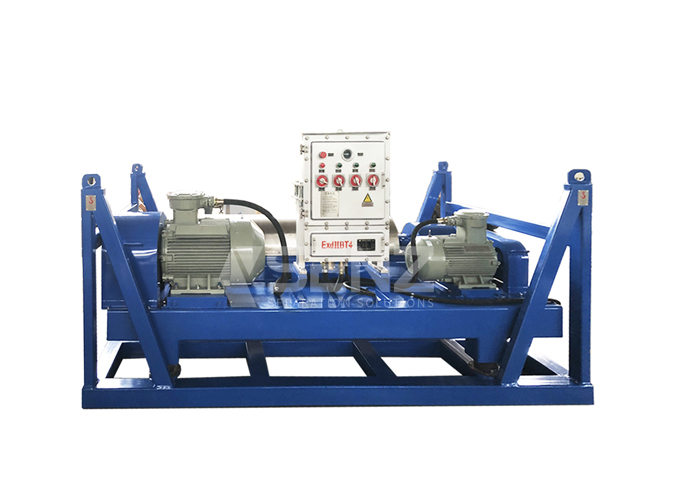

Frequency conversion control is selected to facilitate customers to adjust the speed at any time and meet different working conditions.

Schneider or Siemens are used for electrical components, and double protection of current overload protection and mechanical limit switch are selected.

Technical parameter

Users can reasonably select the working parameters of the centrifuge according to the physical properties of the separated material (suspension), separation requirements, treatment capacity, process requirements and other factors, so as to obtain satisfactory separation effect and economic benefits. Colors and materials can be customized.