Product description

Centrifugal dehydrator is a new type of high-efficiency dehydrating equipment, which adopts a screen free dehydrator to completely solve the phenomenon of screen blockage. After use, users are highly praised. It adopts high-speed rotation without screen to separate materials and water under the action of centrifugal force.

Application

It is mainly used for dehydration and drying after washing all kinds of textile (needle) fabrics, clothing, printing and dyeing, food, hardware, chemical raw materials and latex products. It is widely used in enterprises and institutions such as textile, printing and dyeing, clothing, hotels, hospitals, chemicals, food, hardware, mechanical accessories and latex products. In industry, it is applicable to the dehydration (oil) of various metal parts after grinding and cutting, oil washing, washing, cooling and immersion in antirust liquid. It is applicable to the drying, dehydration and deoiling of hardware, electronic parts, iron filings, aluminum filings and copper filings, as well as electroplating and grinding processing plants, hardware lathe processing plants, hardware fastener plants, etc.

Equipment characteristics

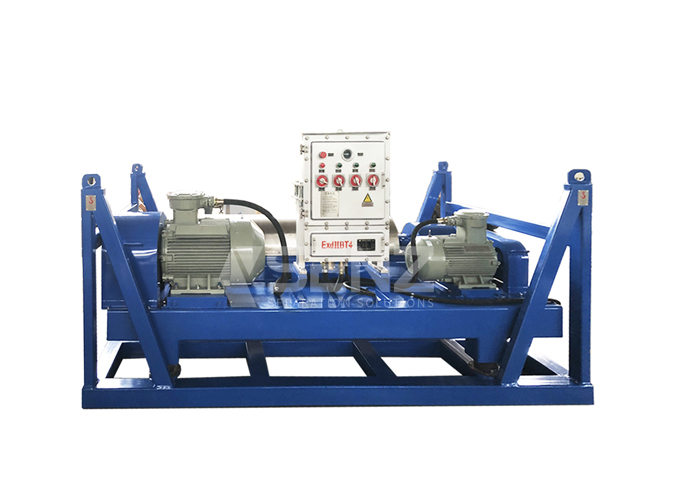

The design is compact. The dehydrator includes electric control cabinet, metering tank, flocculation mixing tank and other devices.

Less faults, less noise and vibration and simple operation

Small floor space for easy maintenance and replacement; Small weight, easy to handle and not easy to block.

It has the function of self-cleaning. There is no need to clean in order to prevent the filter joint from blocking, reduce the water consumption for flushing and reduce the burden of internal circulation.

Good at dewatering oily sludge and low-speed operation.

The rotating speed of the spiral shaft is about 2 ~ 3 rpm, and the electrode consumption is low.

Only the spiral shaft and traveling ring are replaced, which has a long service life.

Through the electric control cabinet, it is connected with the medicine brewing machine, mud inlet pump and dosing pump to realize 24-hour continuous unmanned operation.

The daily maintenance time is short, the maintenance operation is simple and durable.

Almost all the body is made of stainless steel, which can maximize the service life of the equipment.

It is applicable to the dewatering of high and low concentration sludge. When dewatering low concentration (2000mg / L ~) sludge, there is no need to build concentration tank and storage tank, so as to reduce the construction cost, reduce the release of phosphorus and the generation of anaerobic odor.

Routine maintenance

The operator must be familiar with the structure, performance and operation method of the machine.

Turn the fermented bean for several revolutions before starting the machine, and check the transportation of the fermented bean.

The feeding shall be evenly distributed to avoid excessive machine vibration caused by excessive weight.

During normal operation, do not brake the opening and closing arm to avoid damaging the Lanling belt and other parts.

No objects can be placed on the top cover to avoid accidents after startup.

In case of any abnormality during operation, immediately cut off the power supply, brake and stop for inspection.

Material selection

According to the user's requirements, the product contact can be made of austenitic stainless steel (321, 316L...), Haines alloy, titanium alloy or other anti-corrosion materials.

Structure and working principle

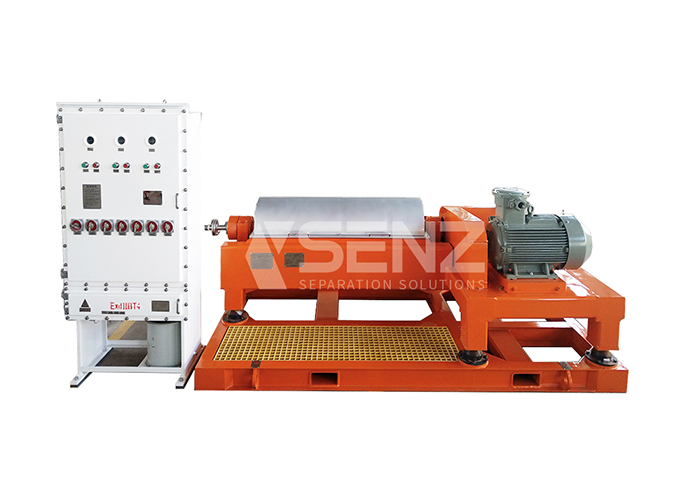

Horizontal screw centrifuge realizes solid-liquid separation by accelerating the settling speed of solid particles under the action of centrifugal force due to the density difference between solid and liquid phases.

The centrifuge is composed of two rotors, one is called drum, and the other rotor is spiral discharger (spiral for short). When the drum rotates at a high speed, the slurry in the drum rotates with the drum and is subjected to centrifugal force, which is many times greater than gravity. In this way, the solid particles will be separated from the liquid and settle on the inner wall of the drum from the axis of the centrifuge drum. The screw unloader in the drum rotates at a speed lower than that of the drum and pushes the deposited solid particles to the slag outlet, The differential speed between the outer drum and the screw unloader depends on the transmission ratio and speed of the differential.

Technical parameter

Users can reasonably select the working parameters of the centrifuge according to the physical properties of the separated material (suspension), separation requirements, treatment capacity, process requirements and other factors, so as to obtain satisfactory separation effect and economic benefits. Colors and materials can be customized.